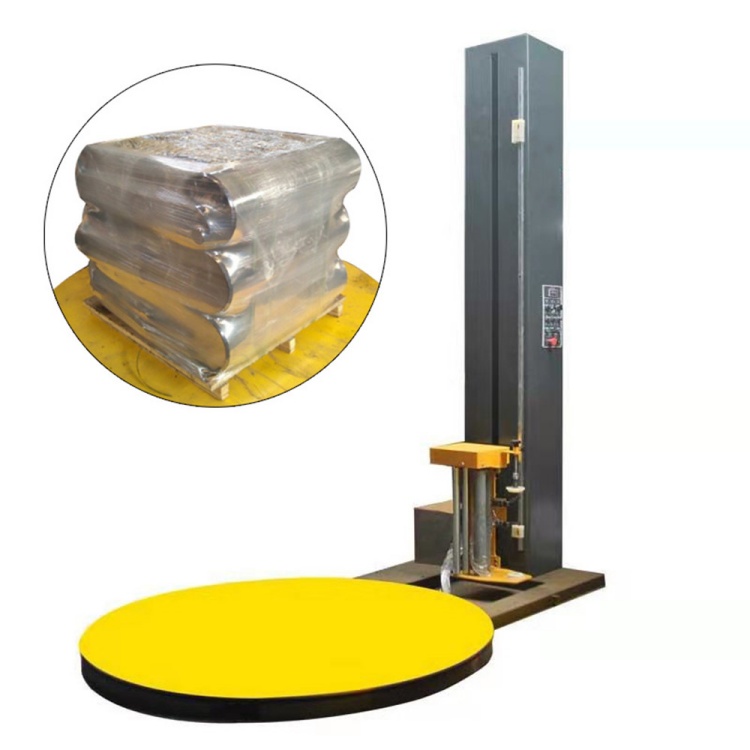

Optimize your packaging line with our highly customizable, labor-saving pallet wrapping machines

In today's fast-paced industrial landscape, efficiency and reliability in pallet wrapping can significantly impact your bottom line. Keepway specializes in engineering advanced pallet wrapping solutions that seamlessly integrate into your operations, reducing labor costs while ensuring superior load stability across diverse applications—from food and beverages to electronics, chemicals, and logistics.

Businesses often overlook how outdated pallet wrapping equipment affects their operational costs:

Labor expenses consuming 40-60% of total packaging costs

Film waste contributing to unnecessary material spending

Product damage during transit due to inconsistent wrapping tension

Production bottlenecks from manual processes

Our pallet wrapping machine series incorporates intelligent features designed to address these challenges directly:

Precision Tension Control: Automated containment force adjustment ensures optimal film application without product damage, reducing film usage by up to 25% compared to manual wrapping.

Adaptive Wrapping Patterns: Customizable programs automatically adjust to load height, weight, and fragility, providing consistent results regardless of operator experience.

Our M-Type-Pallet-Wrapping-Machine features a unique base design that allows easy access for low-profile pallet jacks and manual hydraulic lifts, eliminating the need for expensive loading docks or lifting equipment.

Key Benefits:

Reduced loading height requirements

Ideal for facilities with space constraints

Compatible with all standard pallet types

The Top Platen Pallet Wrapping Machine applies gentle downward pressure during the wrapping process, effectively stabilizing light, bulky items without risk of crushing.

Perfect For:

Door panels and building materials

Insulation products and foam blocks

Empty container stabilization

For operations requiring both accessibility and compression, our hybrid model combines both technologies in a single, space-saving unit.

Our advanced Robot Pallet Wrapping Machine with automatic film threading and cutting represents the pinnacle of wrapping automation, enabling continuous operation without manual intervention.

Features:

Automatic film detection and changeover

Integrated tail sealing for clean film termination

Continuous operation capability for high-volume facilities

Our wrapping-machine-with-rotary-arm is engineered for heavy-duty applications where fixed-position wrapping is preferred, providing exceptional stability for weights up to 4,000kg.

The Horizontal Stretch Wrapping Machine offers an alternative approach for long, awkwardly shaped items that cannot be wrapped using traditional methods, including pipes, extrusions, and dimensional lumber.

A pallet wrapping machine with scale combines two operations in one unit, automatically recording weight data during the wrapping process for inventory tracking and shipping documentation.

The orbital stretch wrapping machine provides complete 360° coverage for irregular-shaped items, ensuring stability without disposable packaging materials.

Our luggage wrapping machine series brings industrial-grade reliability to baggage security applications, with models suitable for airports, logistics centers, and valuable goods transportation.

Remote Monitoring & Diagnostics: Real-time performance tracking and predictive maintenance alerts minimize unexpected downtime.

Energy Efficient Operation: Variable frequency drives and sleep mode functionality reduce power consumption by up to 30% compared to conventional models.

Quick-Change Components: Modular design enables rapid replacement of wear parts, with most service procedures requiring less than 15 minutes.

Integration with existing conveyor systems

Compliance with retail distribution requirements

Weather-resistant models for semi-protected environments

USDA-approved materials for direct product contact zones

Sanitary design with smooth surfaces and easy-clean components

Corrosion-resistant models for high-moisture environments

High-throughput models handling 100+ pallets per hour

Compatible with all major WMS through standardized data interfaces

Minimal maintenance requirements for 24/7 operation

Proven Reliability: With an average MTBF (Mean Time Between Failures) of 8,000+ hours-2, Keepway machines deliver industry-leading reliability that protects your production schedule.

Customization Capabilities: Unlike one-size-fits-all solutions, we engineer our robot pallet stretch film wrapper systems to match your specific requirements, from unique load dimensions to specialized integration needs.

Comprehensive Support: Keepway provides more than equipment—we deliver peace of mind with responsive technical support and readily available spare parts.

As the industry evolves toward greater automation and connectivity-1, Keepway continues to lead with innovations that address real-world challenges. Our machines aren't just about wrapping pallets—they're about optimizing your entire packaging operation for maximum efficiency and reliability.

Request a free, no-obligation packaging analysis from our solutions team. We'll review your current process and recommend the optimal Keepway system for your requirements, complete with a detailed ROI calculation.

For immediate technical specifications or pricing information on our wrapping machines luggage airport series or any of our other specialized equipment, contact our packaging consultants today.

Keepway Packaging Solutions - Engineering Efficiency Into Every Wrap

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China