waste paper baler machine /Baling Press Machine

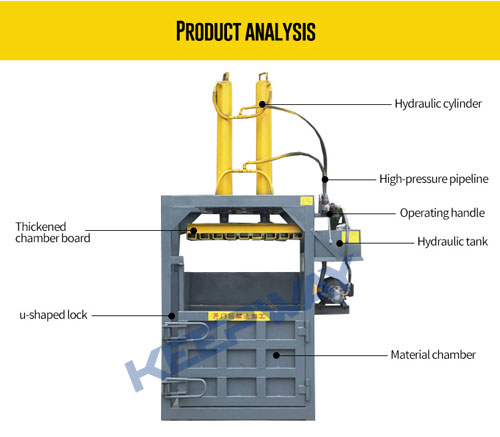

Introduction of Waste paper baler machine/baling press machine:

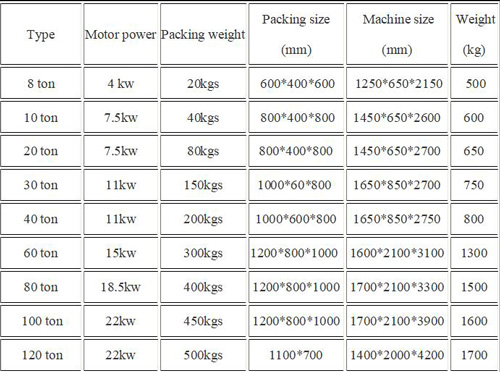

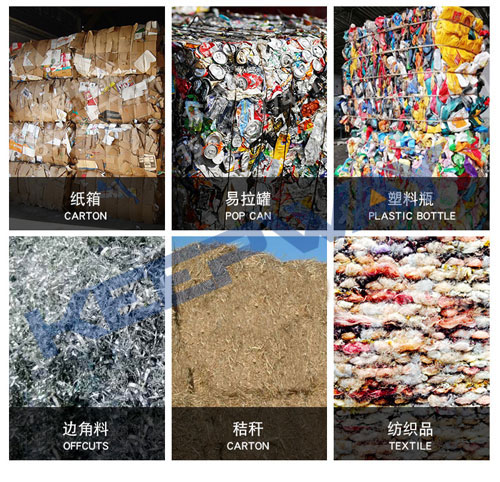

Waste paper baling press machine is mainly used to compress waste paper, plastic bottles, wool, cardboard, cartons, cotton, sand thread, plastic film, woven bags, tires, cans, wheat straw, alfalfa hay, grass, rice husk, peanut shells package.It is designed as vertical structure, hydraulic transmission, electrical control and manual binding.Usually the pressure force of this series is from 10 ton KN to 120 ton KN, the efficiency is 4 ~ 6 pieces per hour. The weight of each piece is from 30 kgs to 500 kgs according to the material.saving space and facilitating storage and transportation

Technology parameter of Vertical Hydraulic Baling Machine:

Features of Waste Paper Baler Machine:

* Applicable to a practical model for small and medium-sized companies to compress garbage.

* No need to install, simple operation.

* U-shaped anti-dropping door handle, easy to unlock, greatly reducing the time cost after packing.

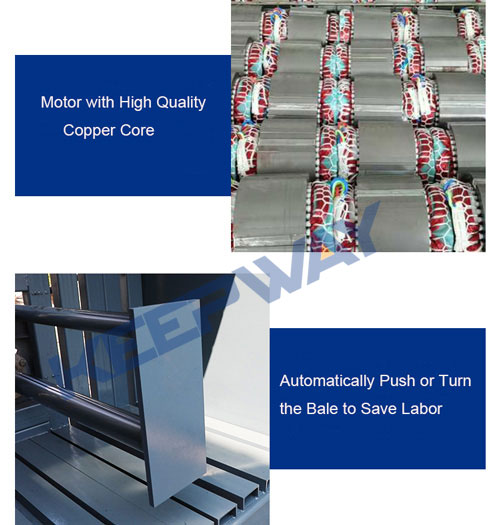

* Motors adopt brand copper core motors with strong power, durability, faster heat dissipation, and guarantee the machine continues to run smoothly.

* Automatically turn over the package, push the package to support customized customization, easy to operate, can be directly after the end of the press work machinery out of the package, effectively saving labor.

* Imported abrasion-resistant and high-sealing oil pipe with thick pipe wall and strong sealing performance of the connection port to ensure the compression work no oil leaks during operation.

* Low failure rate and durable.

What Models We Have:

What Materials Can Bale:

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China