In today's competitive logistics and e-commerce sectors, efficient packaging isn't just a necessity—it's a strategic advantage. If you're spending excessive time and resources on manual carton sealing, the innovative ring-type tape wrapping sealing machine offers a revolutionary solution that automates and optimizes your packaging process.

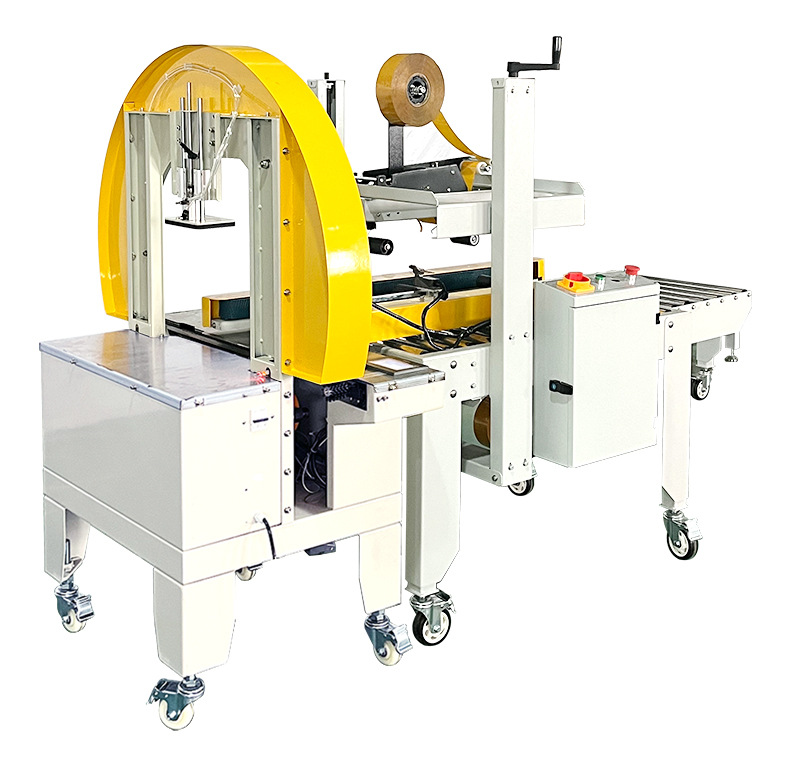

The core mechanism of this advanced packaging machine revolves around a rotating ring system that ensures complete, uniform carton sealing. Here's how it transforms your packaging workflow:

Circular Motion Principle: At the heart of the machine is a circular frame that rotates around stationary cartons. As the ring spins, it dispenses tape evenly across all four sides of your boxes in one continuous motion-1.

Automated Tape Control: The system features precisely calibrated rollers that apply the perfect amount of pressure, ensuring tape adheres smoothly without wrinkles or bubbles, creating a professional finish on every carton-1.

Intelligent Sensing: Advanced models incorporate photoelectric sensors that automatically detect carton height and adjust the wrapping parameters accordingly, ensuring consistent results regardless of box dimensions-6.

This sophisticated yet straightforward approach eliminates the inconsistencies of manual sealing while dramatically increasing output speed.

The automation sequence of a tape wrapping Carton Sealing Machine represents a marvel of packaging engineering:

Automatic Feeding: Cartons are conveyed into the machine through a powered roller system where sensors detect their presence and dimensions-5.

Precise Positioning: The carton is centered within the rotating ring mechanism, ensuring equal clearance on all sides for uniform tape application-1.

Programmed Wrapping: Once activated, the ring begins its rotation around the stationary carton. The number of wrapping cycles is pre-programmable, allowing you to customize tape coverage based on carton strength requirements-6.

Clean Tape Termination: After completing the preset number of rotations, the machine automatically cuts the tape and securely seals the end against the carton surface, leaving no loose edges-1.

The entire process completes in seconds per carton, with minimal operator intervention required once parameters are set.

The adaptability of ring-type tape wrapping machines makes them invaluable across various packaging scenarios:

E-commerce Fulfillment Centers: Perfect for sealing corrugated shipping boxes of different sizes before shipment, providing secure closure that protects contents during transit-1.

Logistics and Distribution: Ideal for sealing foam boxes containing temperature-sensitive products, ensuring contents remain protected from environmental factors-6.

Manufacturing and Assembly Lines: Excellent for sealing four-sided cartons containing finished goods, with consistent results that enhance your brand's professional appearance-1.

The technology particularly shines in environments with high-volume, mixed-size carton flows, where quick changeover between different box dimensions is essential for maintaining throughput.

Recognizing that every facility has unique requirements, quality manufacturers offer extensive customization options:

Ring Diameter Variations: The circular frame can be manufactured in different sizes to accommodate everything from small parcel boxes to oversized shipping containers-5.

Power Configuration Flexibility: Machines can be configured to operate on various voltage standards (110V/220V) and frequencies (50Hz/60Hz) to match regional electrical systems-1.

Conveyor System Adaptations: Integration options range from simple roller conveyors to fully automated belt systems that synchronize with your existing production line-5.

Specialized Tape Compatibility: Equipment can be calibrated to work with various tape types including printed branding tapes, reinforced security tapes, or specialty adhesive formulations-1.

These customization possibilities ensure that the packaging solution fits seamlessly into your specific operational context and volume requirements.

Investing in an automated tape wrapping system delivers measurable returns across multiple dimensions of your operation:

Substantial Labor Savings: Automating the sealing process reallocates human resources to more value-added tasks while reducing dependency on skilled packaging staff-5.

Consistent Quality Assurance: Machine-applied tape creates uniform seals every time, eliminating the variability of manual application and reducing the risk of container failure during shipping-5.

Enhanced Operational Speed: With capabilities to seal up to 30 cartons per minute, these systems easily outperform even the most experienced manual operators-1.

Material Optimization: Precise control over tape application minimizes waste, generating significant savings on consumable costs over time-5.

The combined effect of these benefits typically delivers a surprisingly short return on investment period, often measurable in months rather than years.

The ring-type tape wrapping sealing machine represents more than just another piece of factory equipment—it embodies the transition to smarter, more efficient packaging methodologies. By solving the fundamental challenges of carton sealing through elegant engineering, it enables businesses to enhance productivity while simultaneously reducing costs.

For companies seeking to optimize their packaging operations, this technology offers a compelling solution that grows with your business and adapts to your changing needs.

Discover how our customizable tape wrapping solutions can transform your packaging line. Explore our product page to learn more about the ring-type tape wrapping sealing machine or Contact our packaging specialists for a personalized consultation.

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China