Automatic M Type pallet wrapping machine / Stretch Film Packing Machine

Introduction of M type pallet wrapping machine:

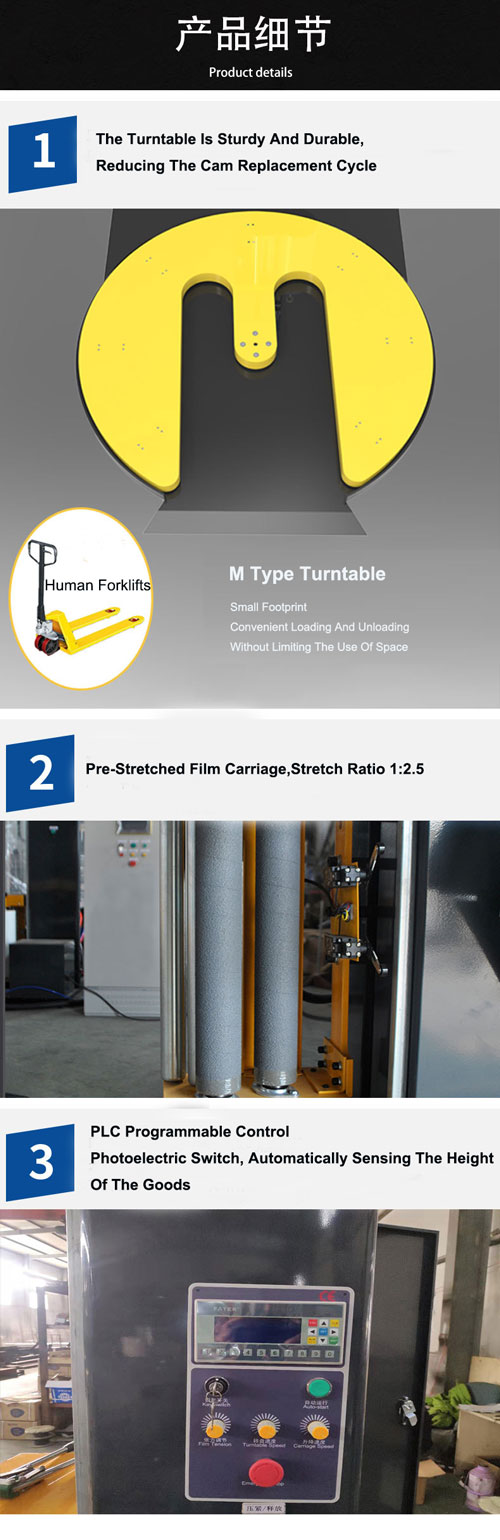

The M type pallet wrapping machine /pallet wrapper / stretch film packing machine uses PE stretch film to wrap bulk pallet goods. The turntable of this machine adopts an M-shaped design, which is suitable for loading and unloading goods with a forklift by hand. It is inconvenient to install slopes and make foundations (for example, it cannot be used as a foundation on the upper floor. ). It is suitable for workshops with relatively clean environment and companies with relatively light goods. It is widely used in glass products, hardware tools, electronic appliances, paper making, ceramics, chemicals, food, beverages, building materials and other industries. This equipment can improve logistics efficiency and reduce transportation The loss in the process has the advantages of dust-proof, moisture-proof and reduced packaging cost.

Technology Parameter of M Type Pallet Wrapping Machine:

Features of M Type Pallet Wrapping Machine:

Control System:

1) With a separate PLC programming control system, the number of winding layers and times can be set;

2) The screen displays the PLC operation display interface;

3) Photoelectric switch, which automatically senses the height of the goods;

4) The top layer, bottom layer, and the number of reciprocating laps can be set individually;

5) The photoelectric switch is turned on and off; the film breaking and film shortage alarm can be set in the operation screen.

6) The machine has the function of detecting faults. If there is a fault, open the "monitoring interface" to monitor the machine failure

7) The device has a one-key restore to factory settings function. When the user adjusts the parameters of the device in confusion, he can press the one-key restore button to restore the factory settings and reset the parameters.

Turntable Drive:

1) Turntable frequency conversion speed regulation 0~12 rpm adjustable;

2) Turntable motor power: 0.75kw

3) The drive of the turntable is a chain drive, and the positioning is accurate;

4) The turntable is automatically reset, which is convenient for loading and unloading goods on the spot.

5) The bottom of the turntable is equipped with a forklift slot.

6) Thickness of chassis steel plate: 10mm

7) Chassis chain: 12A

Film Carriage System:

1) The film carriage is an AC motor pre-stretching mechanism, equipped with frequency conversion speed regulation;

2) Adjusting the film tension, the pre-stretching can reach 250%;

3) 10A double chain structure, stable and reliable;

4) Film carriage lifting motor power: 0.55kw

5) The raising and lowering speeds of the film carriage and the film feeding speed are adjustable by frequency conversion;

6) The wrapping numbers of the top and bottom are separately controlled;

7) Membrane system follow-up mechanism, just pull it;

8) Install a photoelectric switch on the film carriage to automatically detect the height of the goods.

Column Structure:

1) Double chain structure, stable and reliable

2) The lifting chain adopts 10A chain transmission, which has high service life and wear resistance

3) The column has a convenient maintenance module

4) The column box: wall thickness 1.5mm, upper and lower plates 6mm, inner corner reinforcement plate 6mm

Surface Treatment:

The whole machine adopts outdoor plastic powder spraying treatment, which is resistant to abrasion and rust

PLC Programmable Control

Photoelectric Switch, Automatically Sensing The Height Of The Goods

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China