Automatic Side Labeling Machine/Side Label Machine

Introduction of Automatic Side Labeling Machine:

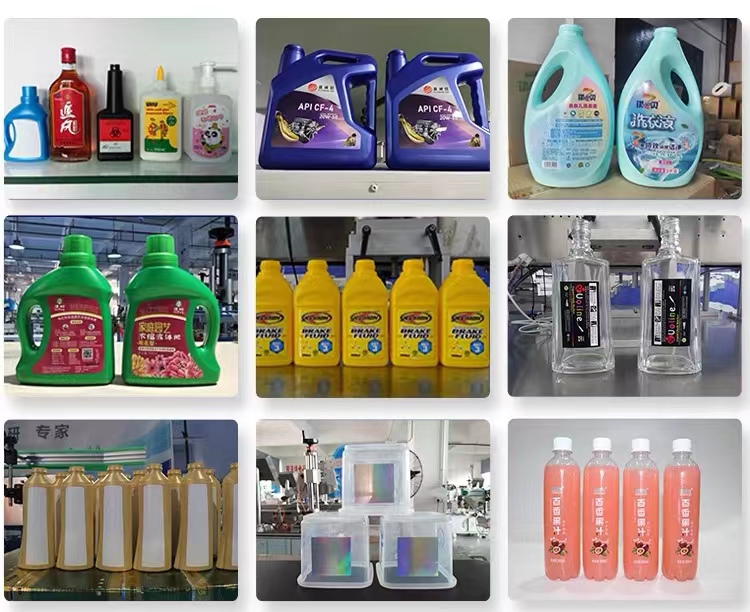

Automatic side labeling machine is suitable for single-sided and double-sided labeling of flat bottles, round bottles and square bottles, such as flat shampoo bottles, lubricating oil flat bottles, hand sanitizer round bottles, etc., and can also be applied on both sides at the same time , Improve production efficiency, widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

Scope of application

(1) Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

(2) Applicable products: products that require labels to be affixed on the side plane, the large arc surface of the side surface, and the circumferential surface.

(3) Application industry: widely used in cosmetics, daily chemicals, electronics, medicine, hardware, plastics and other industries.

Applications:

Shampoo flat bottle labeling, lubricating oil flat bottle labeling, shampoo round bottle labeling, etc.

Labeling range

Technology parameter of Automatic Side Labeling Machine:

Features of Automatic Side Labeling Machine:

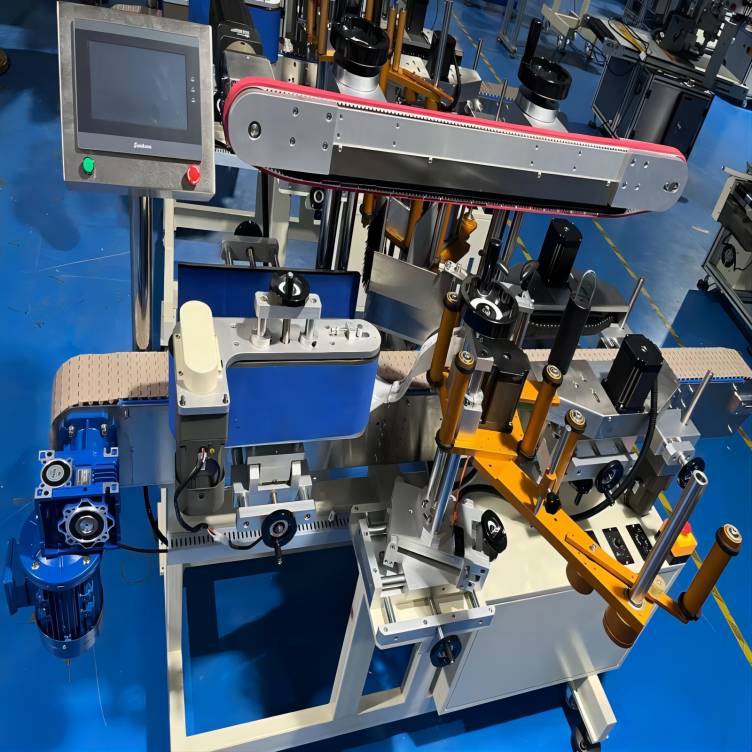

1.Powerful function, one machine can realize single side of multiple products (flat bottle, square bottle, special-shaped bottle);

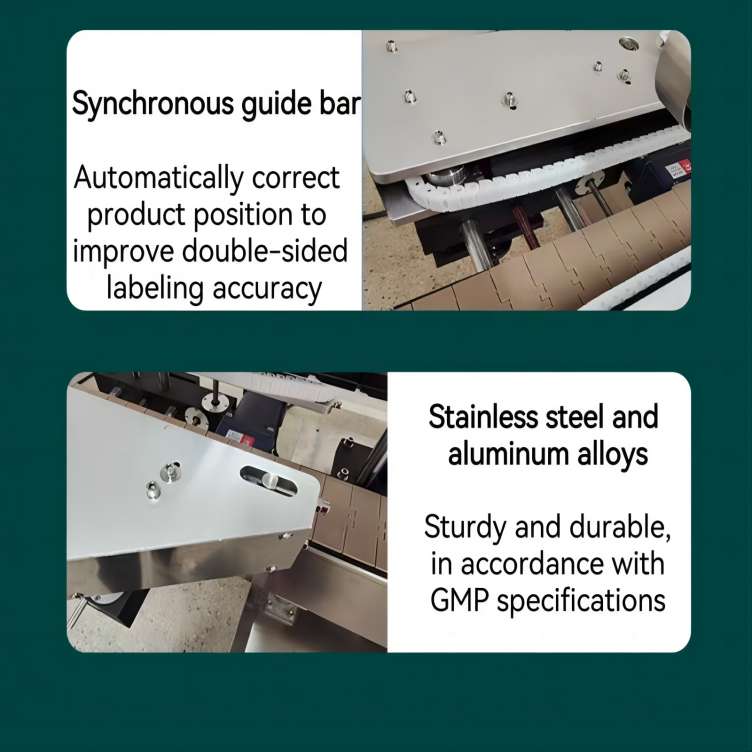

2.Using a double-sided rigid plastic synchronous guide chain, which automatically guarantees the neutrality of the bottle, and has low requirements for the worker to put the bottle and the assembly line to dock the bottle, which greatly reduces the difficulty of the worker's work or the assembly line docking. It can be produced on a single machine or connected to an assembly line;

3.Equipped with elastic pressure topping mechanism to ensure stable product delivery and effectively eliminate the inherent error of bottle height;

4.It is equipped with an automatic bottle separation mechanism, and the spacing is automatically separated before the bottle is guided to ensure the stability of the subsequent bottle guiding, conveying and labeling;

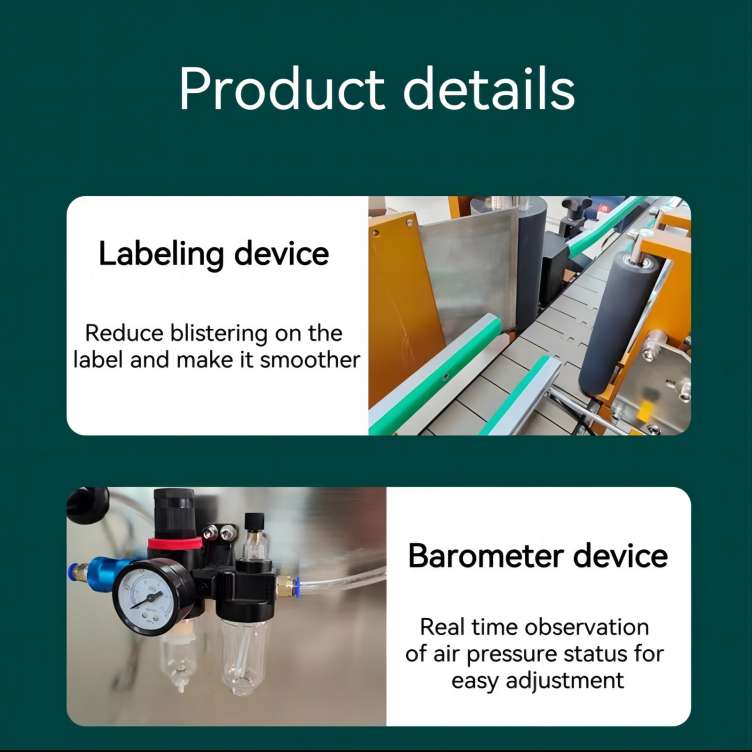

5.It is equipped with a double labeling mechanism to ensure the labeling accuracy for the first time, and the second squeeze labeling can effectively eliminate air bubbles and ensure that the label head and tail are tightly attached;

6.Intelligent control, automatic photoelectric tracking, with no object but no labeling, no label automatic correction and automatic label detection functions, to avoid wasting labels and missing labels;

7.The main material of the equipment is stainless steel and high-grade aluminum alloy, which conforms to GMP production specifications. The overall structure is firm and beautiful.

8.It can be produced on a stand-alone machine, or connected to an assembly line production, with automatic product detection, realizing unmanned production;

9.It has the function of failure shutdown, production counting function, power saving function, production number setting shutdown function, parameter setting protection function, which is convenient for production management;

10.Optional functions and components:

①Hot coding/printing function;

②Automatic feeding function;

③Automatic material collection function (combined with product consideration);

④Add labeling device;

⑤Circumferential positioning and labeling function;

⑥Other functions (customized according to customer requirements).

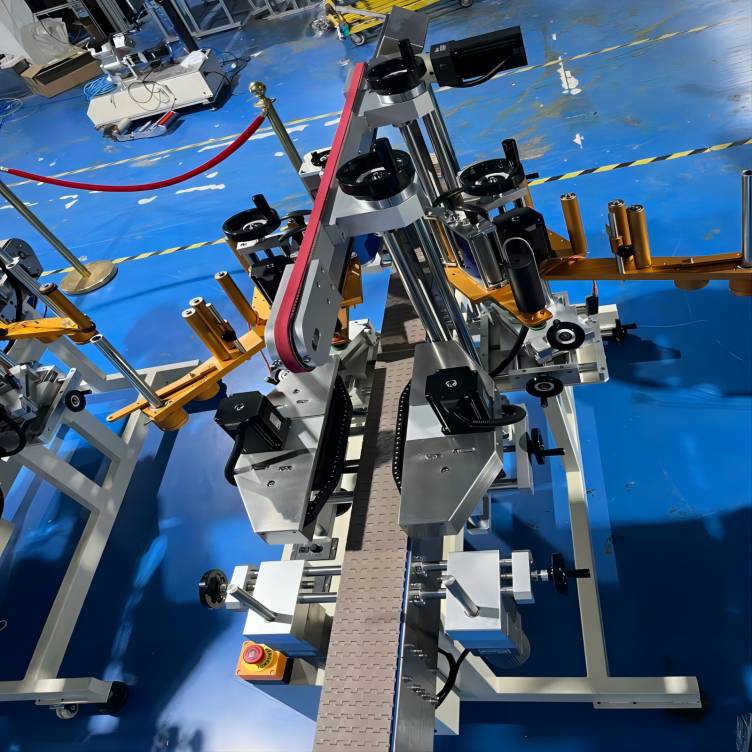

Product real pictures

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China