How to Choose the Right Pallet Wrapping Machine: A Guide to Boosting Efficiency & Cutting Costs

Is your warehouse or factory spending too much time and money on securing pallet loads? Are you experiencing product damage, film waste, or rising labor costs from manual wrapping? You're not alone. For businesses in logistics, manufacturing, and distribution, the pallet wrapping process is a critical final step before shipment. Investing in the right automatic pallet wrapping machine is not just about automation; it's a strategic move to save time, reduce product damage, and significantly increase operational efficiency . This guide will help you understand your options and how to select the best stretch wrapping machine for your needs.

What is a

pallet wrapping machine?

A pallet stretch wrapper is a machine used to wrap stretch film around palletized products. This secures the items to the pallet, preventing movement during transportation or storage. It protects your goods from dust, moisture, and damage, ensuring they arrive in perfect condition . Whether you run a small warehouse or a large distribution center, using a pallet wrap machine ensures load stability and delivers substantial cost savings.

Key Considerations When Choosing Your Machine

Before selecting a machine, a thorough assessment of your warehouse requirements is essential. Here are the key factors to consider, which often align with common customer search queries:

Daily Wrapping Volume: How many pallets do you wrap per day or per shift? This is the primary factor in deciding between a semi-automatic pallet wrapper and a fully automatic pallet wrapper. High-volume operations (e.g., over 50 pallets daily) will see a rapid ROI from a fully automatic machine .

Load Type and Stability: Are you wrapping uniform, stable loads, or do you handle light, heavy, or irregular-shaped loads? Unstable or very heavy loads may require a rotary arm stretch wrapper where the arm moves around a stationary pallet, rather than a turntable model .

Load Size and Height: Accurate measurements of your average and maximum pallet dimensions (both size and height) are crucial to ensure the machine you choose has the required capacity.

Integration Needs: Do you need a standalone pallet wrapping machine, or will it be integrated into an existing conveyorized packaging line? An inline automatic stretch wrapper is designed for seamless integration with conveyor systems for maximum efficiency.

Film Usage and Cost-Saving Goals: Modern machines with powered pre-stretch film technology can stretch film up to 250%-400%, dramatically reducing film consumption and cost. If reducing your material spend is a priority, this feature is a must-have .

Types of Pallet Wrapping Machines

Understanding the different types of machines will help you match the right technology to your operation.

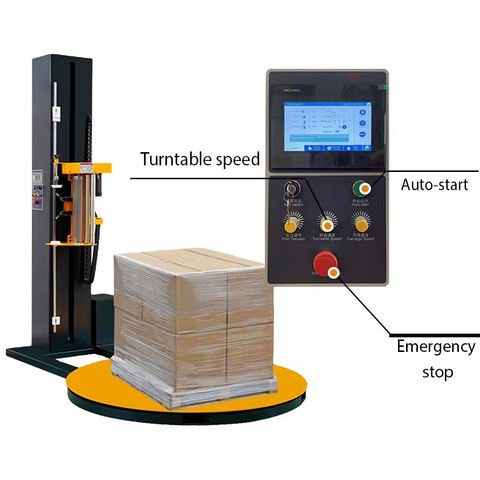

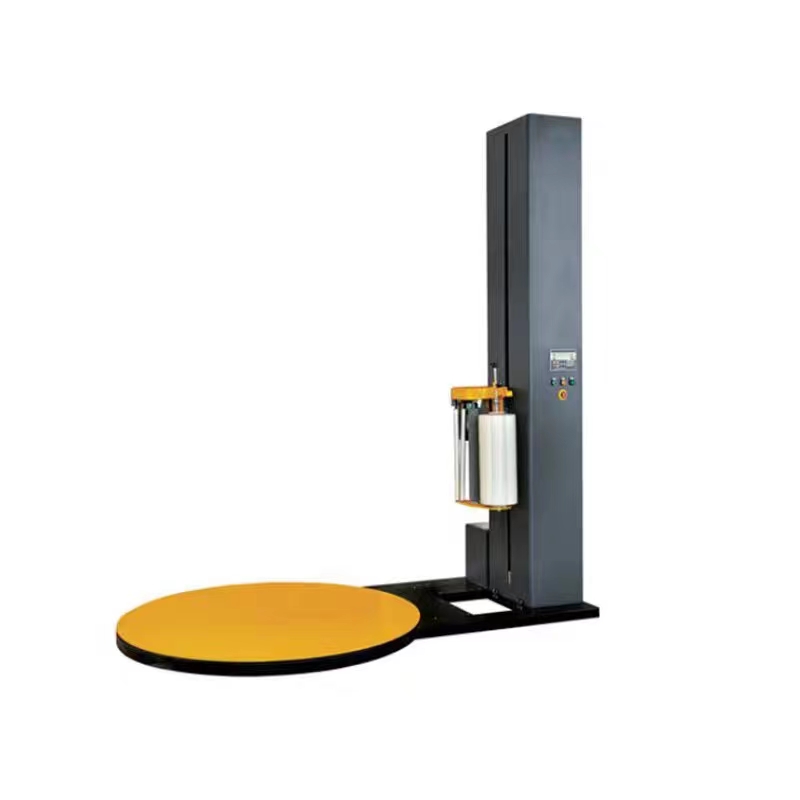

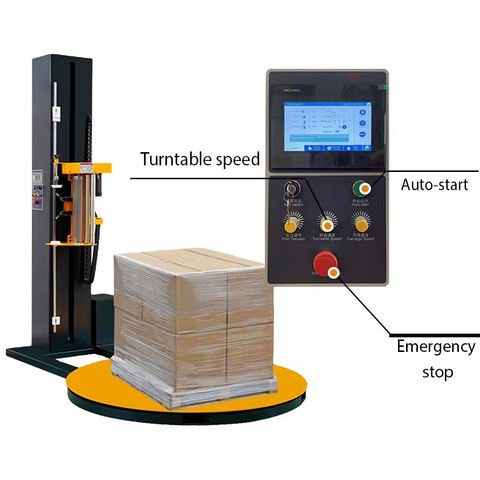

Semi-Automatic Pallet Wrapper: An operator places the film on the load, starts the cycle, and cuts the film at the end. This is a great entry-level option for medium-sized businesses, offering a good balance of automation and cost, with a typical output of up to 25 pallets per hour .

Fully Automatic Pallet Wrapper: This machine operates with complete autonomy. The operator simply places the pallet on the turntable, and the machine does the rest, including film cutting and clamping. Ideal for high-volume warehouses, it offers maximum speed, consistency, and minimal labor, handling up to 60 pallets per hour .

Rotary Arm Stretch Wrapper: Instead of the pallet spinning, a mechanical arm wrapped with film rotates around a stationary load. This is the perfect solution for wrapping unstable, very heavy, or extremely lightweight loads that cannot be spun on a turntable .

Robotic Stretch Wrapper: A highly flexible solution where a robotic arm applies the film. It is mobile, compact, and excellent for wrapping non-standard or very large loads. Its main drawback is a higher initial cost .

The Tangible Benefits of Automating Your Pallet Wrapping

Significant Cost Reduction: Drastically lower your film consumption with advanced pre-stretch technology and reduce labor costs.

Enhanced Load Security: Achieve consistent, uniform wrapping tension every time, which minimizes the risk of load shifting, product damage, and returns.

Increased Productivity: An industrial pallet wrapping machine can wrap pallets far faster and more consistently than a human operator, freeing up your team for higher-value tasks.

Improved Workplace Safety: Automating the wrapping process reduces operator fatigue and the risk of musculoskeletal injuries associated with manual wrapping .

Why Partner with a Specialist Manufacturer?

Choosing a reliable pallet wrapping machine supplier is as important as the machine itself. Look for a manufacturer with a proven in