robot wrapping machine /Mobile Wrapping Machine

Introduction of robot wrapping machine:

Robot pallet wrapping machine /robot stretch wrapper / robot stretch film wrap machine uses LLDPE stretch film as packaging materials and is applied to pallet packaging. it uses the wrapping machine service to package various regular or irregular goods, and utilizes the shrinkage and shrinkage of the stretch film. the self-adhesiveness binds the cargo and the pallet into a whole and plays a fixed role, so the cargo will not be loose and collapsed, and it can also protect the cargo from dust, moisture and damage. it is mainly aimed at a self-moving wrapping packaging machine designed for the user’s packaging that is relatively large and heavy and inconvenient to move. the machine can move by itself while realizing the wrapping of the objects. it is simple to operate and has a low failure rate. it is a user ideal choice.

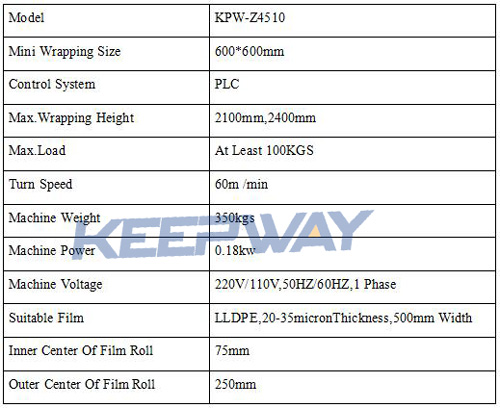

Technology Parameter of Robot Wrapping Machine:

Features of Robot Pallet Wrapping Machine:

1. Controllable selection of a variety of packaging methods. With up and down reciprocating, single up or single down, central fixed position reinforcement.

2. Manually select the working mode and packaging method.

3. Adopt storage battery as power, powerful power and low noise.

4. The packaging is automated, saving space. The self-propelled wrapping machine can be moved at any time, which not only saves the space of the workshop and warehouse, but also facilitates transportation to the site to start work immediately.

5. There is a fast film loading mechanism, which is quick and convenient to wear the film, and the efficiency is high.

6. Adopt programmable program control system. All parameters can be adjusted automatically on the control panel, which adopts liquid crystal display, which is easy to operate.

7. The sensor automatically senses the height of the tray.

8. Suitable for packing pallets of any shape, weight and size.

9. The charging plug is located outside the machine for easy docking.

10. The following parameters can be adjusted from the operation panel:

1) The number of winding turns at the top, the number of winding turns at the bottom, and the number of winding turns back and forth

2) The rising and falling speed of the film frame, the walking speed of the machine

3) Emergency stop switch, pause switch, power display

4) Film out speed of the film frame (the film out tension is adjusted from the knob on the mold frame)

5) The lower limit of the machine running warning signal light. Package object size: 600 x 600mm

Mobile:+86-18206519878

Tel:0086 18206519878

Whatsapp:008618206519878

Email:sales@kbwmachinery.com

Add:Wanda Plaza, Fuqiao Street, Rencheng District, Jining City,Shandong Province,China